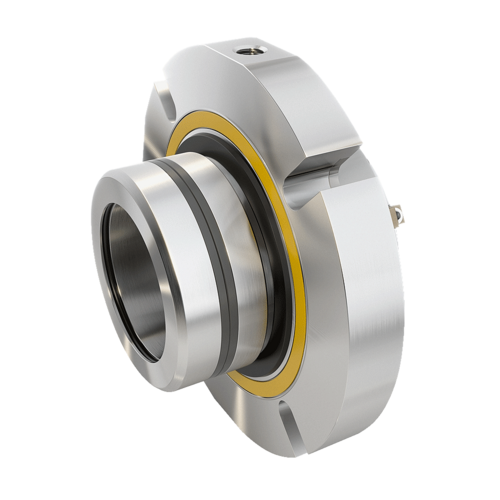

Pump Seals

Price 1500 INR/ Piece

Pump Seals Specification

- Application

- Water pumps, Oil pumps, Chemical pumps, Process pumps

- Theory

- Mechanical Seal Theory, Contact & Non-Contact Sealing

- Hardness

- 60-90 Shore A (Elastomer Components)

- Style

- Balanced, Unbalanced, Cartridge, Pusher, Non-Pusher

- Material

- Carbon, Silicon Carbide, Ceramic, Stainless Steel, Rubber (Elastomer)

- Temperature

- -20C to 200C

- Pressure

- Up to 20 bar

- Speed

- Up to 3000 rpm

- Function

- Sealing rotating pump shafts to prevent leakage

- Size

- 18 mm to 100 mm (Shaft diameter)

- Structure

- Single Spring, Multi-Spring, Wave Spring, Metal Bellows

- Suitable Media

- Clean Water, Light Chemicals, Oils, Mild Acids

- Spring Material

- Stainless Steel 304/316

- Resistance Properties

- Corrosion Resistance, Wear Resistance

- Mounting Type

- Replaceable, Split, Mounted

- Shaft Orientation

- Horizontal & Vertical Shaft Pumps

- Service Life

- Up to 10,000 hours (application dependent)

- Seal Type

- Single Acting, Double Acting

Pump Seals Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 2 Week

About Pump Seals

Versatile Pump Seal Solutions

Engineered for both horizontal and vertical shaft pumps, these pump seals are ideal for clean water, light chemicals, oils, and mild acids. The flexible design accommodates various mounting types such as replaceable, split, and direct mounting, making them suitable for a wide spectrum of industrial and process applications. Their adaptability ensures reliable performance across diverse sectors in India.

Durable Materials and Advanced Structure

Each pump seal incorporates high-grade components including carbon, silicon carbide, ceramic, stainless steel, and robust elastomers. With options such as single spring, multi-spring, wave spring, and metal bellows, these seals cater to specific performance requirements. Stainless Steel 304/316 springs enhance corrosion resistance, extending operational life and ensuring reduced downtime for critical pump systems.

High Performance Standards

These pump seals are designed for pressure applications up to 20 bar and rotational speeds of 3000 rpm, making them suitable for demanding environments. The balanced, unbalanced, cartridge, pusher, and non-pusher styles comply with mechanical seal theory, offering both contact and non-contact sealing. This ensures excellent leak prevention and reliability across a wide temperature range (-20C to 200C).

FAQ's of Pump Seals:

Q: How do I determine the suitable pump seal type for my application?

A: Selecting the appropriate seal type depends on the media you are working with (e.g., clean water, oils, mild acids), the pump's pressure and speed, shaft orientation, and specific operational conditions. For applications up to 20 bar and 3000 rpm, with shaft sizes from 18 mm to 100 mm, these seals offer balanced, unbalanced, cartridge, and other styles to fit diverse requirements.Q: What is the typical service life of these pump seals, and what factors affect it?

A: The service life of these seals can reach up to 10,000 hours, depending on the operating environment, temperature, media, pressure, and maintenance practices. Proper installation and routine checks will ensure longevity and reliable performance.Q: When should I consider using a split or replaceable mounting type seal?

A: Split or replaceable mounting seals are ideal for applications where downtime must be minimized. They allow easy seal replacement without dismantling the pump completely, making them a practical choice for larger or hard-to-service equipment.Q: Where can these pump seals be deployed, and for which pump types are they most suitable?

A: These seals are designed for deployment in water, oil, chemical, and process pumps with both horizontal and vertical shafts. They are widely used across industrial sectors-including manufacturing, processing, and utility operations-throughout India.Q: What is the process for installing a cartridge style pump seal?

A: Cartridge seals simplify installation by being pre-assembled and pre-set, reducing the risk of installation errors. To install, align the seal unit onto the pump shaft, secure as per the manufacturer's guidelines, and ensure proper lubrication before starting the pump.Q: What are the main benefits of using mechanical pump seals with stainless steel 304/316 springs?

A: The use of stainless steel 304/316 springs enhances corrosion and wear resistance, ensuring consistent seal performance even with aggressive or corrosive media. This results in extended service life and fewer maintenance interventions.Q: How do the elastomer components' hardness ratings affect seal performance?

A: A hardness range of 60-90 Shore A for elastomer components ensures optimal flexibility and resilience. This balance helps absorb pump shaft vibrations, maintain effective sealing under varying pressures, and prolong seal life across different operating conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seal Category

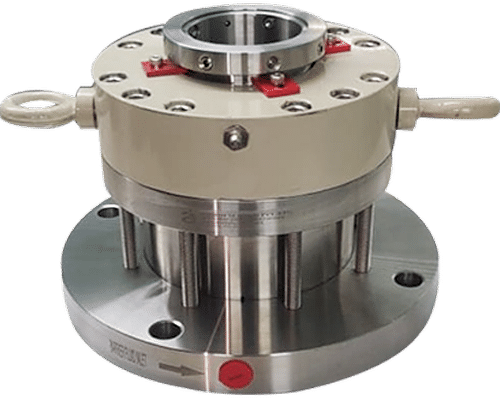

Cartridge Seals

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, SS316, SS304, Carbon, SIC, TC, Ceramic, PTFE, Viton, NBR, EPDM

Structure : Cartridge Mounted Mechanical Seal

Temperature : 20C to 200C

Style : Other, Single/Double Cartridge Design

Agitator Seal

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Stainless Steel, Alloy Steel, Carbon Steel, PTFE, Viton, Carbon, Ceramic, Silicon Carbide, Tungsten Carbide

Structure : Component or Cartridge type with single or double seal arrangement

Temperature : 20C to +200C (varies with materials of construction)

Style : Other, Double Mechanical Seal, Cartridge Seal

Dry Run Seal

Price 15000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Carbon, Silicon Carbide, Tungsten Carbide, Stainless Steel

Structure : Single and double seal structure

Temperature : 40C to 180C

Style : Other, Cartridge type mechanical seal

Multi Spring Seals

Price 1500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, SS316, SS304, HastelloyC, Titanium, Alloy20, Carbon, Ceramic, Silicon Carbide, Tungsten Carbide, PTFE, GFT (Glass Filled Teflon)

Structure : Cartridge and component construction

Temperature : 20C to 200C (Higher on request)

Style : Other, Multispring, nonpusher and pusher type

Send Inquiry

Send Inquiry