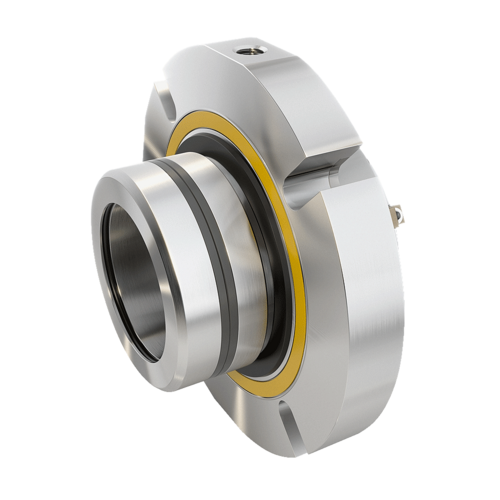

Dry Run Seal

Price 15000.0 INR/ Piece

Dry Run Seal Specification

- Hardness

- Up to 85 HRB

- Application

- Centrifugal pumps, mixers, agitators, and compressors

- Theory

- Contact and non-contact sealing

- Style

- Cartridge type mechanical seal

- Material

- Carbon, Silicon Carbide, Tungsten Carbide, Stainless Steel

- Temperature

- -40°C to 180°C

- Pressure

- Up to 16 bar

- Speed

- Up to 25 m/s

- Function

- Dry running sealing for pumps and agitators

- Size

- 20 mm to 100 mm shaft diameter

- Structure

- Single and double seal structure

Dry Run Seal Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 5 Pieces Per Week

- Delivery Time

- 2 Week

- Main Domestic Market

- All India

About Dry Run Seal

Dry Running seal are designed for agitators, mixers, reactor vessels, blowers, fans, etc. and is basically used on top of the vessel. The seal face is exposed to the gases vapors of the product and there is no liquid media coming in contact with the faces. These seals dont require any external media for lubrication of the faces, hence it is known as Dry running seals.

Balanced Design for High Pressure Operation

Engineered with a balanced configuration, the Dry Run Seal withstands high pressures up to 16 bar and maintains consistent sealing performance. This design feature also prevents excessive wear, ensuring longer service life even in challenging environments such as chemical and oil processing plants.

Versatile Media Compatibility

This seal is compatible with water, oil, a variety of chemicals, and dry running. It meets industry standards, including API 682 and EN12756, ensuring reliable sealing across multiple application scenarios. The use of robust materials like carbon, silicon carbide, tungsten carbide, and stainless steel enhances media resistance.

Effortless Installation and Maintenance

Supplied as a pre-assembled cartridge, the Dry Run Seal simplifies mounting and reduces installation time. Its design accommodates up to 1.5 mm axial movement and supports both single and double seal structures, making maintenance straightforward and minimizing the risk of incorrect assembly.

FAQ's of Dry Run Seal:

Q: How is the Dry Run Seal installed and does it require specialized tools?

A: The Dry Run Seal features a pre-assembled cartridge design, allowing for simple installation without specialized tools. It is mounted directly onto the shaft, making the process straightforward and reducing downtime during seal replacement.Q: What are the benefits of using different face combinations like Carbon vs Sic and TC vs TC?

A: The various face combinations, such as Carbon vs Silicon Carbide and Tungsten Carbide vs Tungsten Carbide, provide flexibility for different media and operating conditions. These options enhance wear resistance and durability, ensuring optimal performance in water, oil, chemical, and dry running applications.Q: When should Viton, EPDM, NBR, or FFKM elastomers be selected?

A: Elastomer selection depends on the chemical compatibility and temperature requirements of the application. Viton is suited for oil and chemicals at higher temperatures, EPDM is ideal for water and low-temperature operations, NBR handles oils and greases, while FFKM excels in aggressive chemical environments.Q: Where can the Dry Run Seal be used?

A: This mechanical seal is suitable for centrifugal pumps, mixers, agitators, and compressors across industries such as water treatment, chemical processing, and oil refining. Its robust design and compliance with international standards make it versatile for various installations.Q: What process ensures zero visible leakage in dry conditions?

A: The combination of balanced seal design, precise face pairing, and high-quality elastomers ensures reliable contact and non-contact sealing. These attributes collectively contribute to zero visible leakage under dry operational modes.Q: What advantages does the multiple springs, corrosion-resistant feature offer?

A: Multiple corrosion-resistant springs maintain consistent seal pressure against the rotary shaft, compensating for shaft movement and wear over time. This design reduces maintenance frequency and increases the seal's operational life, especially in aggressive media.Q: How does the seal accommodate axial movement and maintain sealing performance?

A: The Dry Run Seal allows up to 1.5 mm axial float, enabling it to handle shaft misalignment or thermal expansion without compromising sealing integrity or leakage prevention.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seal Category

Cartridge Seals

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Pumps, Agitators, Mixers, Chemical Process Industries

Temperature : 20°C to 200°C

Structure : Cartridge Mounted Mechanical Seal

Function : Rotary Sealing

Single Spring Seal

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Pumps, Compressors, Mixers, Agitators

Temperature : 20°C to +180°C

Structure : Single Coil Spring, Mating Ring, Primary Seal, Secondary Seals

Function : Sealing rotating shafts to prevent leakage

Multi Spring Seals

Price 1500 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Petrochemical, Chemical, Fertilizer, Oil & Gas, Pharmaceuticals, Water Treatment, Pumps, Compressors, Agitators

Temperature : 20°C to 200°C (Higher on request)

Structure : Cartridge and component construction

Function : Balanced and Unbalanced sealing applications

Pump Seals

Price 1500 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Water pumps, Oil pumps, Chemical pumps, Process pumps

Temperature : 20°C to 200°C

Structure : Single Spring, MultiSpring, Wave Spring, Metal Bellows

Function : Sealing rotating pump shafts to prevent leakage

Send Inquiry

Send Inquiry