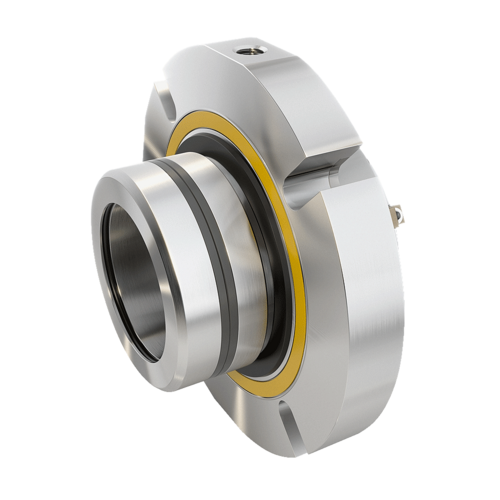

Agitator Seal

Price 10000 INR/ Piece

Agitator Seal Specification

- Hardness

- Shore A 60-90 (seal face materials)

- Theory

- Seal operates on mechanical face sealing principle

- Application

- Reactors, Agitated Vessels, Mixers in Chemical, Pharmaceutical, and Food Industries

- Style

- Double Mechanical Seal, Cartridge Seal

- Material

- Stainless Steel, Alloy Steel, Carbon Steel, PTFE, Viton, Carbon, Ceramic, Silicon Carbide, Tungsten Carbide

- Temperature

- -20°C to +200°C (varies with materials of construction)

- Pressure

- Up to 10 bar (varies by model and application)

- Speed

- Up to 3000 RPM

- Function

- To seal agitator shafts and prevent leakage of liquids or gases

- Size

- Available in shaft sizes from 20 mm to 150 mm or as per customer specification

- Structure

- Component or Cartridge type with single or double seal arrangement

- Medium

- Corrosive liquids, slurries, solvents

- Shaft Alignment Tolerance

- ±0.1 mm

- Seal Faces

- Multi-spring design with balanced faces

- Finish

- Surface finish ≤0.2 Ra for wetted parts

- Mounting

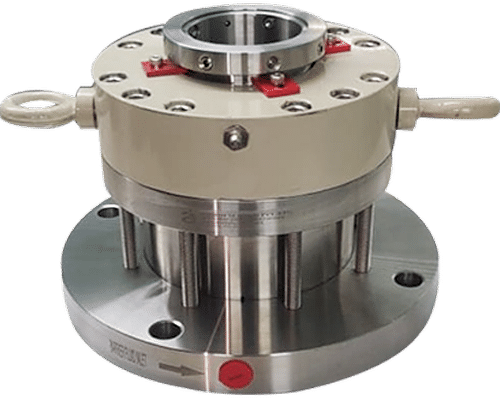

- Top or side entry as per vessel design

- Cooling Arrangement

- Provision for quench, drain and cooling water

- Elastomers

- FEP, EPDM, Nitrile

- Leakage Rate

- Very low, as per industrial standards

- Replacement Cycle

- Designed for extended operational life with easy maintenance

Agitator Seal Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 2 Week

- Main Domestic Market

- All India

About Agitator Seal

A mechanical seal is a device used to effect a seal between a rotating or reciprocating part and a stationary part on an Agitator / Mixer / Vessel. A mechanical seal works by creating a restrictive flow path, this is either an axial or radial gap. The flow through this gap is generally so low it goes unnoticed if a liquid or inconsequential if a gas.Exceptional Sealing Performance

This seal delivers very low leakage rates, adhering to stringent industrial standards for agitator applications in chemical, pharmaceutical, and food processing sectors. The precisely balanced multi-spring seal faces combined with high-grade elastomers ensure consistent integrity against aggressive process media.

Flexible Mounting and Cooling Solutions

Designed to accommodate both top and side vessel entries, the seal offers versatile installation options. Advanced cooling arrangements, including quench, drain, and cooling water provisions, effectively manage thermal loads during high-speed or high-temperature operations, enhancing reliability.

Easy Maintenance and Extended Service Life

With an intelligently structured cartridge and component design, maintenance is straightforward and downtime is minimized. Premium surface finish for wetted parts and robust construction materials ensure the seal withstands harsh process conditions while maintaining long operational life.

FAQ's of Agitator Seal:

Q: How does the Agitator Seal maintain a very low leakage rate during operation?

A: The seal uses a multi-spring design with balanced faces and surface finish 0.2 Ra for wetted parts, optimizing even pressure across the faces and preventing fluid escape. This configuration is engineered to meet stringent industrial standards for leakage control.Q: What benefits do the specialized elastomers like FEP, EPDM, and Nitrile provide in this seal?

A: These elastomers offer excellent chemical resistance, flexibility, and durability, making the seal effective for corrosive liquids, solvents, and slurries used in diverse industrial processes, thus enhancing reliability and service life.Q: When is maintenance recommended for the Agitator Seal, and is the process complicated?

A: Maintenance intervals are extended thanks to the robust design. When needed, the cartridge arrangement allows for rapid replacement with minimal downtime or specialized tools, simplifying maintenance procedures.Q: Where can this Agitator Seal be used within industrial facilities?

A: It is ideal for reactors, agitated vessels, and mixers found in chemical, pharmaceutical, and food industries, and suits both new installations and retrofit projects in operations handling corrosive or high-load media.Q: What is the process behind installing the Agitator Seal on different vessels?

A: The seal's design permits either top or side entry mounting, with sizes ranging from 20 mm to 150 mm shafts or as per user specifications. Installation typically involves securing the cartridge or component design onto the shaft per vessel design and connecting the cooling and quench lines.Q: How does the cooling arrangement improve the performance and lifespan of the seal?

A: Provision for quench, drain, and cooling water efficiently regulates temperatures, prevents media crystallization near seal faces, and reduces wear, which collectively prolongs the seal's operational life and maintains stable performance under demanding conditions.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seal Category

Cartridge Seals

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, SS316, SS304, Carbon, SIC, TC, Ceramic, PTFE, Viton, NBR, EPDM

Size : 25mm to 100mm shaft size

Style : Other, Single/Double Cartridge Design

Structure : Cartridge Mounted Mechanical Seal

Multi Spring Seals

Price 1500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, SS316, SS304, HastelloyC, Titanium, Alloy20, Carbon, Ceramic, Silicon Carbide, Tungsten Carbide, PTFE, GFT (Glass Filled Teflon)

Size : Shaft sizes from 18 mm to 100 mm

Style : Other, Multispring, nonpusher and pusher type

Structure : Cartridge and component construction

Pump Seals

Price 1500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Carbon, Silicon Carbide, Ceramic, Stainless Steel, Rubber (Elastomer)

Size : 18 mm to 100 mm (Shaft diameter)

Style : Other, Balanced, Unbalanced, Cartridge, Pusher, NonPusher

Structure : Single Spring, MultiSpring, Wave Spring, Metal Bellows

Cartridge Mechanical Seal

Minimum Order Quantity : 1 Piece

Material : Other, Stainless Steel / Carbon / Ceramic / Silicon Carbide / TC

Size : 25 mm to 100 mm (shaft diameter)

Style : Other, Single Cartridge Seal

Structure : Multispring, Cartridge, Oring or bellow design

Send Inquiry

Send Inquiry