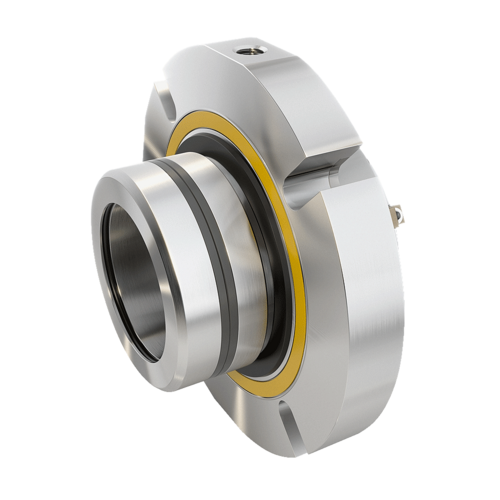

Cartridge Seals

Price 40000 INR/ Piece

Cartridge Seals Specification

- Hardness

- 65-85 Shore A (Elastomer), 80-90 HRB (Metal Parts)

- Theory

- Balanced, Unbalanced Mechanical Seal

- Application

- Pumps, Agitators, Mixers, Chemical Process Industries

- Style

- Single/Double Cartridge Design

- Material

- SS316, SS304, Carbon, SIC, TC, Ceramic, PTFE, Viton, NBR, EPDM

- Temperature

- -20C to 200C

- Pressure

- Up to 25 bar

- Speed

- Up to 25 m/s

- Function

- Rotary Sealing

- Size

- 25mm to 100mm shaft size

- Structure

- Cartridge Mounted Mechanical Seal

- Standards

- DIN 24960, EN 12756 compliant

- Corrosion Resistance

- High, Suitable for Aggressive Media

- Dynamic Runout Tolerance

- Up to 0.05 mm

- Spring Type

- Multiple Springs

- Shaft Direction

- Bi-directional

- O-Ring Material

- Viton, EPDM, NBR

- Seal Face Combination

- Carbon vs Ceramic/SIC/TC

- Leakage Rate

- Low, Conforms to International Standards

- Replaceability

- Interchangeable with Standard Mechanical Seals

- Mounting Type

- Pre-assembled Cartridge Unit

- Maintenance

- Easy Installation and Removal

- Flushing Connection

- Provided for cooling/lubrication

Cartridge Seals Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Western Union, Cash Advance (CA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Cheque

- Supply Ability

- 5 Pieces Per Week

- Delivery Time

- 2 Week

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Central America, Eastern Europe, Asia, North America, Africa

- Main Domestic Market

- All India

About Cartridge Seals

Reliable Cartridge Mounted Design

Our cartridge-mounted mechanical seals deliver outstanding reliability for pumps, agitators, and mixers. Offered in both single and double cartridge styles, these units come pre-assembled for simple installation and quick removal, reducing downtime and minimizing maintenance effort. Multiple springs ensure consistent sealing force and robust performance in demanding operational environments.

Superior Material and Corrosion Resistance

Manufactured with high-quality SS316, SS304, carbon, SIC, TC, ceramic, PTFE, and elastomers like Viton, NBR, and EPDM, these seals provide exceptional chemical and corrosion resistance. They are ideal for handling aggressive process media, making them suitable for use in chemical process industries, water treatment facilities, and other harsh industrial environments.

International Standards Compliance and Versatility

Our seals comply with DIN 24960 and EN 12756 standards, guaranteeing interchangeability and consistent quality across international applications. Available in sizes from 25mm to 100mm shaft diameter, they accommodate a wide variety of equipment and offer both balanced and unbalanced sealing options for diverse process requirements.

FAQ's of Cartridge Seals:

Q: How are these cartridge seals installed and removed?

A: These cartridge-mounted mechanical seals are pre-assembled units designed for straightforward installation and removal. The user simply mounts the cartridge onto the pump or equipment shaft and secures it, minimizing the need for complex alignment or adjustments. This feature reduces downtime and simplifies maintenance procedures.Q: What materials are used in the construction of these seals, and why?

A: The seals are constructed with high-quality materials such as SS316, SS304, carbon, silicon carbide (SIC), tungsten carbide (TC), ceramic, PTFE, Viton, NBR, and EPDM. These materials are chosen for their outstanding corrosion and chemical resistance, making them suitable for aggressive process media and extending the seal's operational lifespan.Q: When should I opt for a single versus double cartridge seal design?

A: Single cartridge seals are typically used for less demanding applications or where leakage containment is not critical. Double cartridge seals are preferred in hazardous or aggressive environments where additional containment and safety are required, providing extra protection against media leakage.Q: Where can these seals be used?

A: These cartridge seals are suitable for a range of rotating equipment such as pumps, agitators, and mixers. Typical applications include chemical process industries, water treatment plants, petrochemical facilities, and any environment that requires robust, corrosion-resistant sealing solutions for fluids or slurries.Q: What is the benefit of the bi-directional shaft rotation capability?

A: The bi-directional design allows the seal to perform efficiently regardless of the shaft's rotational direction. This is advantageous in equipment where the shaft may operate in both directions, ensuring reliable sealing performance and versatility.Q: How does the flushing connection improve performance?

A: The provided flushing connection allows for cooling or lubrication of the seal faces, reducing heat buildup and extending seal life. This feature is especially useful in high-speed or high-pressure applications or when handling abrasive or viscous media.Q: Are these seals interchangeable with standard mechanical seals?

A: Yes, the seals conform to international DIN 24960 and EN 12756 standards, ensuring compatibility and easy replacement with other standard cartridge mechanical seals in existing equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seal Category

Single Spring Seal

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Style : Other, Single Spring

Size : 12 mm to 100 mm (Shaft Diameter)

Structure : Single Coil Spring, Mating Ring, Primary Seal, Secondary Seals

Material : Other, Stainless Steel, Carbon, Ceramic, Viton, NBR

Pump Seals

Price 1500 INR / Piece

Minimum Order Quantity : 1 Piece

Style : Other, Balanced, Unbalanced, Cartridge, Pusher, NonPusher

Size : 18 mm to 100 mm (Shaft diameter)

Structure : Single Spring, MultiSpring, Wave Spring, Metal Bellows

Material : Other, Carbon, Silicon Carbide, Ceramic, Stainless Steel, Rubber (Elastomer)

Conical Spring Seals

Price 1500 INR / Piece

Minimum Order Quantity : 1 Piece

Style : Other, Single Coil Conical Spring

Size : 16 mm to 100 mm shaft diameter

Structure : Conical Spring, Mating Ring, Rotating Face, Elastomeric Bellows

Material : Other, Carbon, Ceramic, Silicon Carbide, Stainless Steel, Viton, Nitrile, PTFE

Rubber Bellow Seal

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Style : Bellow Seal

Size : Standard

Structure : Flexibility

Material : Rubber

Send Inquiry

Send Inquiry