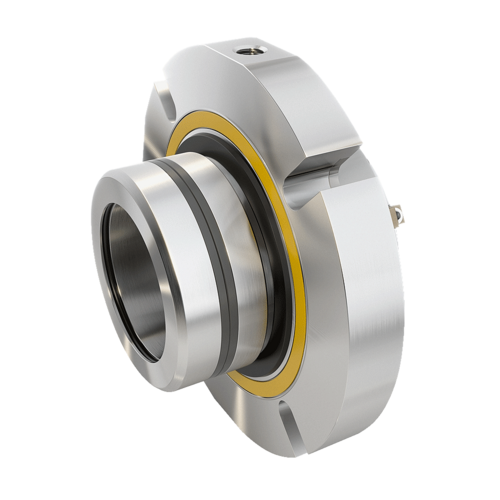

Single Spring Seal

Price 2000 INR/ Piece

Single Spring Seal Specification

- Application

- Pumps, Compressors, Mixers, Agitators

- Hardness

- 55-75 Shore A (Elastomer)

- Theory

- Mechanical Seal

- Style

- Single Spring

- Material

- Stainless Steel, Carbon, Ceramic, Viton, NBR

- Temperature

- -20C to +180C

- Pressure

- Up to 12 bar

- Speed

- Up to 3000 rpm

- Function

- Sealing rotating shafts to prevent leakage

- Size

- 12 mm to 100 mm (Shaft Diameter)

- Structure

- Single Coil Spring, Mating Ring, Primary Seal, Secondary Seals

Single Spring Seal Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 2 Week

- Main Domestic Market

- All India

About Single Spring Seal

Single Spring Seals are single helical coil spring, bi-directional seal developed for usage where media is dirty and clogging type. Internally mounted seal, therefore suitable for wide-spread applications. Torque is transmitted by drive lugs from drive collar to spring holder and seal rings. All components are held together by snap ring which helps in easier installation and removal.

Industrial Application:

- Process Industries, Oil Refinery, Pharmaceutical, Solvents, Paper & Pulp Industries etc.

Face Materials:

- Tungsten Carbide, Carbon, Silicon Carbide, Ceramic, Special Cast.

Metal Component:

- S.S 304, S.S 316, Alloy 20, Hastelloy C.

Secondary Seal:

- Viton, TTV, FKM, NBR, EPR, PTFE.

Operating Limits:

- Pressure: 12 bar

- Temperature : -20C to 140C

- Speed : 10 m/s

Reliable Performance in Dynamic Environments

This single spring rotary shaft seal is ideal for demanding applications that require consistent leak prevention, high corrosion resistance, and accommodation for shaft misalignment. Its precision face lapping ensures minimal friction, maximizing both efficiency and operational lifespan. You can trust its robust construction for long-lasting service in various industrial settings including pumps, mixers, compressors, and agitators.

Effortless Maintenance and Installation

Designed with easy replacement and assembly in mind, this seal simplifies routine maintenance and reduces operational downtime. The pusher type arrangement allows for quick disassembly and reassembly, making it an excellent solution for users who value both convenience and reliable performance. Whether you are a dealer, distributor, or end user, the installation process is straightforward.

Comprehensive Media Compatibility

Engineered to handle water, oil, mild chemicals, and light slurries, this rotary shaft seal offers broad media compatibility. Its corrosion-resistant materials and robust housing ensure protection against varied operational conditions, making it suitable for almost any industrial liquid sealing application encountered by manufacturers, traders, and exporters.

FAQ's of Single Spring Seal:

Q: How does the single spring seal accommodate misalignment and axial movement in shafts?

A: The single spring seal features a design that compensates for minor shaft misalignment and axial movement, thanks to its flexible single coil spring and pusher type assembly. This ensures effective sealing performance even in dynamically shifting conditions.Q: What materials are used in the construction of this single spring seal, and why?

A: This seal uses a combination of stainless steel, carbon, ceramic, Viton, NBR, and PTFE or metal-encased housings to achieve excellent corrosion resistance, leak prevention, and chemical compatibility with common operating media such as water, oil, and mild chemicals.Q: When should this single spring seal be selected over other types of rotary shaft seals?

A: Choose this single spring seal when high corrosion resistance, dynamic leak-proofing, the ability to handle both shaft rotation directions, and easy maintenance are key requirements. It is particularly suitable for applications involving moderate pressure, higher speeds, and exposure to mild chemicals or slurries.Q: Where is this seal typically installed and what applications does it serve?

A: This seal is commonly used in pumps, compressors, mixers, and agitators across sectors such as manufacturing, water treatment, and chemical processing. Its broad compatibility makes it suitable for installations by manufacturers, dealers, exporters, retailers, and suppliers alike.Q: What is the process for installing or replacing this single spring seal?

A: Installation involves cleaning the shaft, aligning the seal components, and assembling the pusher and spring elements according to manufacturer guidelines. The seal's design makes replacement straightforward, allowing for quick disassembly and reassembly with standard tools.Q: What benefits does the dynamic and static leak-proofing provide to users?

A: Dynamic and static leak-proofing ensures reliable containment of process fluids, reducing downtime, maintenance costs, and risks of environmental contamination. This feature is vital for industries prioritizing safety and operational efficiency.Q: Is this seal suitable for high-speed or high-pressure applications?

A: Yes, the single spring seal supports operational speeds up to 3000 rpm and pressures up to 12 bar, making it suitable for a range of mid- to high-range industrial machinery tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seal Category

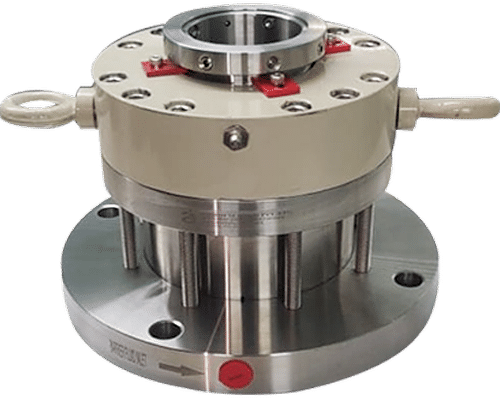

Cartridge Seals

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Pumps, Agitators, Mixers, Chemical Process Industries

Hardness : 6585 Shore A (Elastomer), 8090 HRB (Metal Parts)

Structure : Cartridge Mounted Mechanical Seal

Pressure : Up to 25 bar

Dry Run Seal

Price 15000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Centrifugal pumps, mixers, agitators, and compressors

Hardness : Up to 85 HRB

Structure : Single and double seal structure

Pressure : Up to 16 bar

Agitator Seal

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Reactors, Agitated Vessels, Mixers in Chemical, Pharmaceutical, and Food Industries

Hardness : Shore A 6090 (seal face materials)

Structure : Component or Cartridge type with single or double seal arrangement

Pressure : Up to 10 bar (varies by model and application)

Pump Seals

Price 1500 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Water pumps, Oil pumps, Chemical pumps, Process pumps

Hardness : 6090 Shore A (Elastomer Components)

Structure : Single Spring, MultiSpring, Wave Spring, Metal Bellows

Pressure : Up to 20 bar

Send Inquiry

Send Inquiry