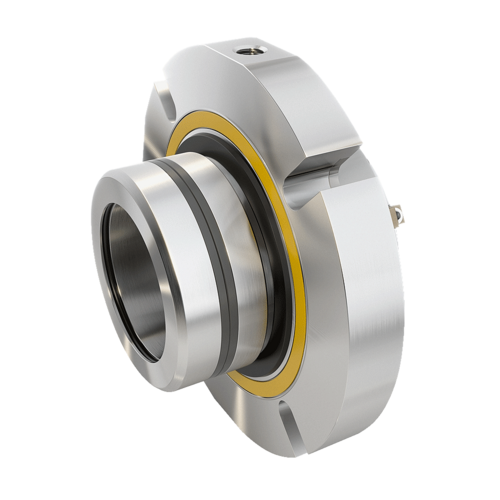

Multi Spring Seals

Price 1500 INR/ Piece

Multi Spring Seals Specification

- Hardness

- Up to 70 HRC (Seal Faces)

- Theory

- Multiple springs provide uniform torque transmission

- Application

- Petrochemical, Chemical, Fertilizer, Oil & Gas, Pharmaceuticals, Water Treatment, Pumps, Compressors, Agitators

- Style

- Multispring, non-pusher and pusher type

- Material

- SS316, SS304, Hastelloy-C, Titanium, Alloy-20, Carbon, Ceramic, Silicon Carbide, Tungsten Carbide, PTFE, GFT (Glass Filled Teflon)

- Temperature

- -20C to 200C (Higher on request)

- Pressure

- Up to 25 bar

- Speed

- Up to 25 m/s

- Function

- Balanced and Unbalanced sealing applications

- Size

- Shaft sizes from 18 mm to 100 mm

- Structure

- Cartridge and component construction

Multi Spring Seals Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 2 Week

About Multi Spring Seals

Superior Leakage Protection and Durability

Engineered for zero leakage, these multi spring seals use a fine lapped seal face finish (Ra < 0.5 m) and premium elastomers to ensure long-lasting performance even under high pressure (up to 25 bar) and high-speed conditions (up to 25 m/s). The combination of advanced materials and multiple springs delivers uniform torque, extending service life and reliability for any rotating equipment.

Flexible Application and Mounting Options

Our seals offer both externally and internally mounted styles, making them adaptable to diverse installation scenarios. The compact construction with interchangeable faces facilitates quick replacement and minimal downtime, while the ability to accommodate moderate shaft misalignment further enhances operational flexibility in pumps, compressors, agitators, and other rotating machinery.

Wide Compatibility for Challenging Environments

Select from a wide range of face materials - Carbon, Ceramic, Silicon Carbide, Tungsten Carbide - matched with top-tier elastomers (Viton, EPDM, PTFE, FFKM) and metals (SS316, Hastelloy-C, Alloy-20, Titanium). This versatility ensures compatibility with aggressive chemicals and harsh operating conditions, making the seals suitable for chemical, petrochemical, oil & gas, and pharmaceutical industries.

FAQ's of Multi Spring Seals:

Q: How does the multi spring design enhance seal performance?

A: Multi spring seals utilize several evenly distributed springs, which provide consistent face loading and uniform torque transmission. This design compensates for normal wear, pressure variations, and moderate shaft misalignment, resulting in improved sealing efficiency and extended service life.Q: What are the key benefits of carbon vs ceramic, silicon carbide, or tungsten carbide face combinations?

A: Carbon vs ceramic provides excellent chemical resistance and is suitable for moderate applications. Silicon carbide and tungsten carbide faces offer outstanding hardness and durability, ideal for abrasive or high-pressure environments, reducing wear and ensuring longer seal longevity.Q: When should I use externally mounted versus internally mounted multi spring seals?

A: Externally mounted seals are preferred when easy access and maintenance are required, while internally mounted designs are chosen for space constraints or in applications where the seal is exposed to the process fluid. The choice depends on system design and operational requirements.Q: Where are multi spring seals commonly used?

A: These seals are widely applied in industries such as petrochemical, chemical, fertilizers, oil & gas, pharmaceuticals, and water treatment, particularly in equipment like pumps, compressors, and agitators, where reliability and zero leakage are crucial.Q: What is the installation process for compact, interchangeable face seals?

A: Installation involves selecting the suitable mounting (internal or external), ensuring the shaft and seal components are clean, placing the seal assembly onto the shaft, and securing it per manufacturer guidelines. The interchangeable face design simplifies replacement and reduces equipment downtime.Q: How do the material options contribute to the seal's chemical and temperature resistance?

A: Material choices like SS316, Hastelloy-C, Titanium, and advanced elastomers (PTFE, FFKM) enable the seal to withstand aggressive chemicals, wide temperature ranges (-20C to 200C), and meet demanding operational conditions without compromising sealing performance.Q: What are the main usage and operational advantages of these multi spring seals?

A: Key advantages include zero leakage, operational compatibility up to 25 bar pressure, high-speed capacity (up to 25 m/s), bi-directional rotation suitability, and the ability to handle shaft misalignment. This makes them a reliable choice for critical process applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seal Category

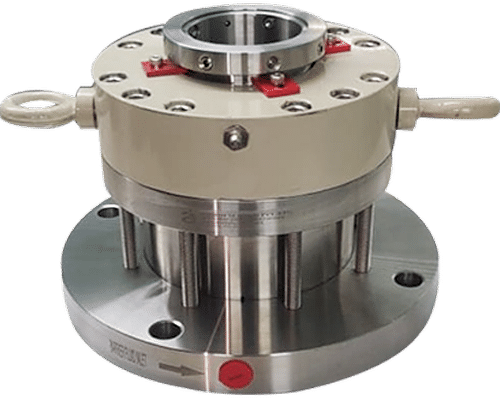

Cartridge Seals

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Cartridge Mounted Mechanical Seal

Temperature : 20C to 200C

Material : Other, SS316, SS304, Carbon, SIC, TC, Ceramic, PTFE, Viton, NBR, EPDM

Style : Other, Single/Double Cartridge Design

Dry Run Seal

Price 15000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Single and double seal structure

Temperature : 40C to 180C

Material : Other, Carbon, Silicon Carbide, Tungsten Carbide, Stainless Steel

Style : Other, Cartridge type mechanical seal

Agitator Seal

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Component or Cartridge type with single or double seal arrangement

Temperature : 20C to +200C (varies with materials of construction)

Material : Other, Stainless Steel, Alloy Steel, Carbon Steel, PTFE, Viton, Carbon, Ceramic, Silicon Carbide, Tungsten Carbide

Style : Other, Double Mechanical Seal, Cartridge Seal

Conical Spring Seals

Price 1500 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Conical Spring, Mating Ring, Rotating Face, Elastomeric Bellows

Temperature : 20C to +200C depending on materials

Material : Other, Carbon, Ceramic, Silicon Carbide, Stainless Steel, Viton, Nitrile, PTFE

Style : Other, Single Coil Conical Spring

Send Inquiry

Send Inquiry