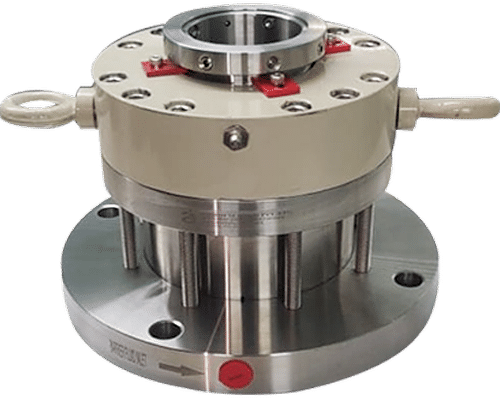

Cartridge Mechanical Seal

Cartridge Mechanical Seal Specification

- Hardness

- Up to 85 HRC

- Application

- Pumps, Mixers, Agitators and Blenders

- Theory

- Balanced mechanical cartridge seal

- Style

- Single Cartridge Seal

- Material

- Stainless Steel / Carbon / Ceramic / Silicon Carbide / TC

- Temperature

- -20C to +200C

- Pressure

- Up to 20 bar

- Speed

- Up to 25 m/s

- Function

- Sealing of rotating equipment to prevent leakage

- Size

- 25 mm to 100 mm (shaft diameter)

- Structure

- Multi-spring, Cartridge, O-ring or bellow design

Cartridge Mechanical Seal Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Export Market(s)

- Asia, Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America

- Main Domestic Market

- All India

About Cartridge Mechanical Seal

Double Cartridge seal are special purpose multi spring Balanced Mechanical Seal designed for abrasive and corrosive media. Independent of direction of rotation. Easy installation because of Cartridge construction. Rugged design improves operating life.

Exceptional Compatibility and Reliability

This mechanical seal is engineered for versatility, covering a wide shaft diameter range from 25 mm to 100 mm, making it suitable for multiple applications. Its construction from high-grade materials such as Stainless Steel, Carbon, Ceramic, Silicon Carbide, and TC guarantees long-term reliability with minimal leakage, less than or equal to 0.1 ml/hr.

Advanced Sealing Performance for Harsh Environments

With features like multi-spring technology and bi-directional operation, this cartridge seal provides consistent sealing performance in pumps, mixers, blenders, and agitators. The design supports high pressure and speed, offers excellent corrosion resistance, and is suitable for a wide temperature span, ensuring durability in demanding chemical and industrial environments.

FAQ's of Cartridge Mechanical Seal:

Q: How is a cartridge mechanical seal installed and used in rotating equipment?

A: Cartridge mechanical seals are pre-assembled units designed for straightforward installation onto the shaft of pumps, mixers, blenders, or agitators. The cartridge design simplifies the mounting process, reduces installation errors, and ensures reliable performance by maintaining correct spring tension and alignment.Q: What are the benefits of using bi-directional and balanced cartridge mechanical seals?

A: Bi-directional and balanced designs enable the seal to perform efficiently regardless of the shaft's rotation direction, while balanced construction reduces seal face loading at high pressures, minimizing wear, extending service life, and supporting more demanding process conditions.Q: When should I choose Viton, NBR, EPDM, or PTFE secondary seals for my application?

A: The choice depends on process fluids and operating conditions. Viton provides excellent chemical and heat resistance; NBR is great for standard oil and fuel applications; EPDM excels in hot water and steam; PTFE handles highly aggressive chemicals and extreme temperatures. Selecting the right elastomer ensures optimal sealing and longevity.Q: What materials are available for the rotary and stationary seal rings, and why does it matter?

A: Rotary rings are available in Stainless Steel, Carbon, and Silicon Carbide, while stationary rings come in Ceramic or TC. Material compatibility ensures high wear resistance and chemical durability, allowing the seal to perform reliably with various process media and under harsh operational conditions.Q: Where can these cartridge mechanical seals be applied?

A: These mechanical seals are suitable for industrial applications such as power plants, chemical processing, oil and gas, food and beverage, pharmaceuticals, and water treatment plants, specifically in equipment like pumps, mixers, agitators, and blenders.Q: How does the seal achieve excellent leakage control and what is the certification level?

A: The cartridge seal's balanced, precision-engineered structure, high-quality materials, and advanced design limit leakage to 0.1 ml/hr. It is manufactured to meet API 682, DIN, and ISO standards, ensuring compliance with international industry regulations.Q: What is the process for selecting the right cartridge mechanical seal for my needs?

A: Selection involves matching the seal's size, material, secondary seals, pressure, temperature, and media compatibility with your application's requirements. Consulting a supplier or manufacturer with your process data supports optimal choices for shaft diameter, face combination, and elastomer selection.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seal Category

Dry Run Seal

Price 15000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Carbon, Silicon Carbide, Tungsten Carbide, Stainless Steel

Style : Other, Cartridge type mechanical seal

Structure : Single and double seal structure

Size : 20 mm to 100 mm shaft diameter

Agitator Seal

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Stainless Steel, Alloy Steel, Carbon Steel, PTFE, Viton, Carbon, Ceramic, Silicon Carbide, Tungsten Carbide

Style : Other, Double Mechanical Seal, Cartridge Seal

Structure : Component or Cartridge type with single or double seal arrangement

Size : Available in shaft sizes from 20 mm to 150 mm or as per customer specification

Multi Spring Seals

Price 1500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, SS316, SS304, HastelloyC, Titanium, Alloy20, Carbon, Ceramic, Silicon Carbide, Tungsten Carbide, PTFE, GFT (Glass Filled Teflon)

Style : Other, Multispring, nonpusher and pusher type

Structure : Cartridge and component construction

Size : Shaft sizes from 18 mm to 100 mm

Rubber Bellow Seal

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Rubber

Style : Bellow Seal

Structure : Flexibility

Size : Standard

Send Inquiry

Send Inquiry