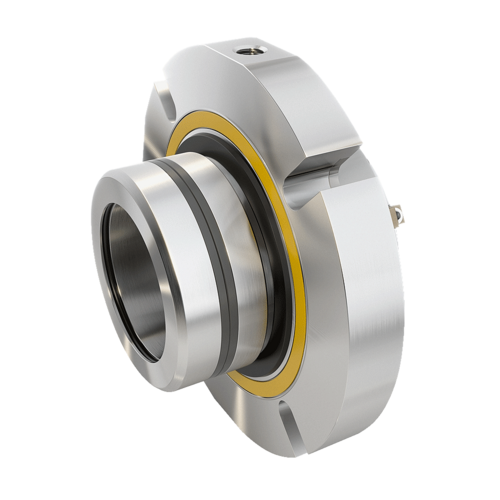

Conical Spring Seals

Price 1500 INR/ Piece

Conical Spring Seals Specification

- Hardness

- 5570 Shore A (elastomers)

- Application

- Pumps, Compressors, Agitators, Mixers, Processing Equipment

- Theory

- Mechanical Seal with balanced design

- Style

- Single Coil Conical Spring

- Material

- Carbon, Ceramic, Silicon Carbide, Stainless Steel, Viton, Nitrile, PTFE

- Temperature

- -20C to +200C depending on materials

- Pressure

- Up to 10 bar

- Speed

- Up to 25 m/s

- Function

- Sealing rotating equipment shafts to prevent leakage

- Size

- 16 mm to 100 mm shaft diameter

- Structure

- Conical Spring, Mating Ring, Rotating Face, Elastomeric Bellows

- Installation Type

- Cartridge and Component Type

- Spring Position

- Outside/Inside of product medium

- Seal Face Options

- Ceramic, Carbon, Silicon Carbide, Tungsten Carbide, Chrome Steel

- Secondary Sealing

- O-rings, PTFE wedges, Rubber Bellows

- Direction of Rotation

- Bi-directional

- Compliance

- Meets international standards (DIN, ISO, API)

- Surface Finish

- Ra 0.6 m for seal faces

Conical Spring Seals Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 2 Week

About Conical Spring Seals

Versatile Seal Face Materials

Select from advanced materials like Ceramic, Carbon, Silicon Carbide, Tungsten Carbide, and Chrome Steel for optimal compatibility with various process media. This flexibility allows for longevity and efficiency in diverse industrial conditions, minimizing wear and maximizing operational uptime.

Reliable Sealing Performance

Designed with a balanced conical spring and a high-quality elastomer (5570 Shore A hardness), these seals assure exceptional sealing integrity. Whether installed on the inside or outside of the product medium, they provide leak prevention in challenging environments under high pressure and speed.

Broad Industrial Applications

Conical Spring Seals are ideally suited for use in pumps, compressors, agitators, mixers, and a broad spectrum of processing equipment. Their adaptable configuration and material diversity make them a preferred choice for manufacturers, suppliers, and operators across the Indian industrial sector.

FAQs of Conical Spring Seals:

Q: How do conical spring seals prevent leakage in rotating equipment?

A: Conical spring seals utilize a mechanical sealing mechanism comprising a conically wound spring, seal faces, and secondary elastomers to create a tight yet dynamic barrier around rotating shafts. This balanced structure effectively prevents process fluid leakage, even during high-speed or high-pressure operation.Q: What are the benefits of choosing different seal face materials?

A: Selecting from materials like Ceramic, Carbon, Silicon Carbide, or Tungsten Carbide provides chemical, thermal, and wear resistance that suits specific application needs. The right material enhances seal reliability, extends service life, and reduces maintenance costs.Q: When should conical spring seals be employed in industrial setups?

A: These seals are ideal for applications where reliable shaft sealing is critical, such as in pumps, compressors, agitators, and mixers operating under varying pressures, temperatures, and speeds. They are particularly useful when media compatibility and compliance with DIN, ISO, or API standards are required.Q: What is the recommended installation process for conical spring seals?

A: Conical spring seals can be installed as component or cartridge types. Follow manufacturer guidelines to ensure the correct alignment of the seal faces, choose appropriate secondary sealing elements, and confirm proper spring compression to guarantee leak-free operation.Q: Where can conical spring seals be sourced in India?

A: These seals are widely available across India through authorized dealers, distributors, exporters, manufacturers, retailers, and wholesalers. Many suppliers offer customization options to match specific shaft sizes and operating conditions.Q: How does direction of rotation affect seal performance?

A: The conical spring mechanical seal is designed for bi-directional rotation, ensuring consistent performance regardless of shaft rotation direction. This feature makes them adaptable for various equipment configurations without the need for additional customization.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seal Category

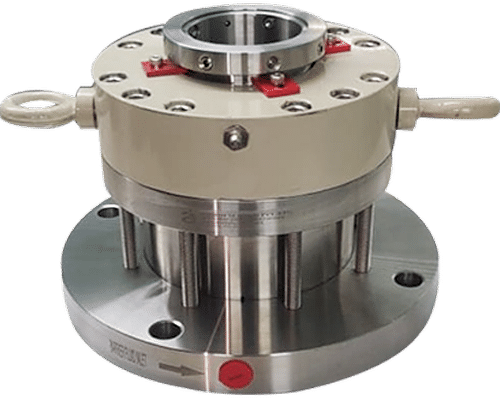

Cartridge Seals

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Theory : Balanced, Unbalanced Mechanical Seal

Material : Other, SS316, SS304, Carbon, SIC, TC, Ceramic, PTFE, Viton, NBR, EPDM

Function : Rotary Sealing

Structure : Cartridge Mounted Mechanical Seal

Dry Run Seal

Price 15000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Theory : Contact and noncontact sealing

Material : Other, Carbon, Silicon Carbide, Tungsten Carbide, Stainless Steel

Function : Dry running sealing for pumps and agitators

Structure : Single and double seal structure

Agitator Seal

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Theory : Seal operates on mechanical face sealing principle

Material : Other, Stainless Steel, Alloy Steel, Carbon Steel, PTFE, Viton, Carbon, Ceramic, Silicon Carbide, Tungsten Carbide

Function : To seal agitator shafts and prevent leakage of liquids or gases

Structure : Component or Cartridge type with single or double seal arrangement

Single Spring Seal

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Theory : Mechanical Seal

Material : Other, Stainless Steel, Carbon, Ceramic, Viton, NBR

Function : Sealing rotating shafts to prevent leakage

Structure : Single Coil Spring, Mating Ring, Primary Seal, Secondary Seals

Send Inquiry

Send Inquiry