Fiber Glass Fabric

Price 10000 INR/ Piece

Fiber Glass Fabric Specification

- Structure

- Cross-woven

- Flat Tempered

- No

- Features

- Fire resistant, corrosion resistant, excellent electrical insulation, dimensional stability

- Strength

- High tensile strength

- Finish Type

- Uncoated

- Transparency

- Translucent

- Bent Tempered

- No

- Glass Type

- E-glass

- Tolerance

- 0.05 mm

- Material

- Fiberglass

- Thickness

- 0.2 mm to 0.8 mm

- Weight

- 200-600 g/m

- Surface

- Smooth

- Density

- 2.55 Gram per cubic centimeter(g/cm3)

- Composition

- Woven fiberglass yarn

- Technique

- Woven

- Pattern

- Plain weave

- Color

- White

- Moisture Absorption

- <0.1%

- Roll Length

- 50 m or customized

- Temperature Resistance

- Up to 550°C

- Flammability

- Non-flammable

- Application

- Electrical insulation, Heat protection, Waterproofing, Roofing, FRP products

- Breaking Strength

- > 600 N/25mm (warp/fill)

- Roll Width

- 1000 mm to 1250 mm

Fiber Glass Fabric Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Fiber Glass Fabric

Fiberglass Cloth

It is woven by best quality texturized glass fiber yarn, it was a high-quality, warm-keeping thermal insulator, it is the ideal substitute for the asbestos cloth. The texturized glass fiber cloth can be offered to insert the copper wire (or nickel wire, stainless steel wire ) . The surface of the texturized glass fiber cloth with rubber can be offered.

Spec: Thickness:0.2mm-6.0mm

Width:1000mm

Refractoriness: 450

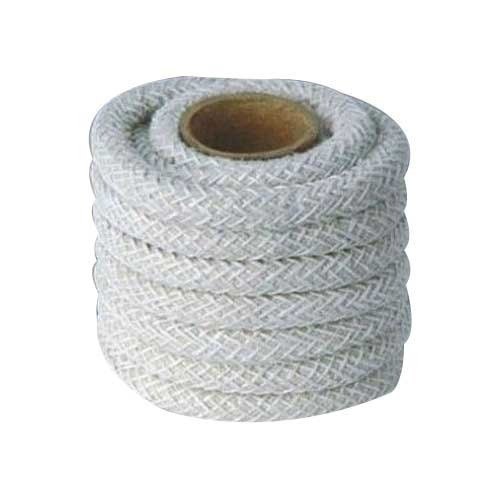

Fiberglass Tape

Wove with the fiberglass, had good insulation and heat resistance, extensively apply to building, waterproof, antiseptic, and wrapping up the coil of electrical machinery and electrical apparatus. It is an excellent substitute for asbestos tape. Texturized glass fiber tape with metallic (copper wire, nickel wire or stainless wire) is also available.

Spec: Thickness: 0.8mm-6.0mm

Width:19mm-200mm

Refractoriness: 450

Fiberglass Rope

It is woven by texturized glass fiber yarn.It is used for the material of keeping warm , insulating against heat etc. It is an excellent substitute for asbestos. The ropes with metallic (copper wire, nickel wire, or stainless wire) are also available.

Spec:3mm-50mm

Versatile Protection for Extreme Conditions

Specifically designed to perform under demanding conditions, this fiberglass fabric withstands high temperatures and is inherently fire and corrosion resistant. Its non-flammable and moisture-repellent nature ensures safety and reliability, even in environments exposed to heat or water. Its cross-woven structure and dimensional stability further enhance its robustness, making it ideal for industrial, commercial, and construction use.

Wide Range of Industrial Applications

This fiberglass fabric is extensively used for electrical insulation, heat protection, waterproofing, roofing, and reinforcing FRP products. Its compatibility across various industries stems from its smooth surface, high tensile strength, and excellent insulation properties. Whether used in manufacturing or on-site construction, its adaptability guarantees efficiency and effectiveness.

Customizable to Project Requirements

Available in roll widths from 1000 mm to 1250 mm and lengths up to 50 meters, this fiberglass fabric can also be tailored to meet specific project needs. Its thickness tolerance of 0.05 mm ensures consistency and precision. As an uncoated material, it is easy to handle and integrate into multiple fabrication processes.

FAQ's of Fiber Glass Fabric:

Q: How does fiberglass fabric provide heat and fire protection?

A: Fiberglass fabric is woven from E-glass yarn, giving it the ability to resist temperatures up to 550C. Its non-flammable composition helps prevent fire spread, making it exceptionally suitable for thermal insulation and heat protection applications.Q: What makes this fiberglass fabric an effective material for electrical insulation?

A: Due to its high dielectric strength, low moisture absorption (<0.1%), and dimensional stability, this fabric ensures reliable electrical insulation, protecting equipment and infrastructure from electrical hazards.Q: When should I choose this fabric for waterproofing or roofing projects?

A: Whenever you need materials that are not only waterproof but also resistant to high temperatures and corrosion, this fiberglass fabric is an optimal choice for roofing membranes and waterproofing layers.Q: Where can this fabric be installed or utilized?

A: This fabric is widely used across industries in India, including electrical, construction, roofing, and manufacturing of FRP products. Its versatility makes it suitable for both indoor and outdoor applications.Q: What is the process of installing or integrating fiberglass fabric in FRP products?

A: The fabric is typically layered and impregnated with resin, then molded into the desired shape to reinforce FRP products. Its plain weave and smooth surface ensure optimal resin penetration and bonding.Q: How does its structure and finish benefit the end user?

A: Its cross-woven, plain-weave structure imparts high tensile strength and dimensional stability, while the uncoated, smooth surface allows for easy handling, cutting, and processing.Q: What are the core benefits of choosing this fabric for industrial applications?

A: Key advantages include fire and corrosion resistance, excellent electrical insulation, exceptional strength, low moisture absorption, and adaptability to various custom sizes-making it a dependable and efficient material for numerous industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry