CL-150 Control Valves

Price 3500 INR/ Piece

CL-150 Control Valves Specification

- Mounting Type

- Vertical / Horizontal

- Capacity

- Up to 500 m/hr

- Connection

- Flanged Ends

- Valve Type

- Control Valve

- Application

- Industrial Automation, Process Control

- Noise Level

- Low

- Pressure Ratings

- 150# (PN 16 as standard)

- Sealing

- PTFE / Metal To Metal

- Diameter

- DN15 to DN200

- Voltage

- 220V AC / 24V DC (for electric models)

- Flow Rate

- Depends on Valve Size and Cv Value

- IP Rating

- IP54/IP65 (for actuators)

- Standard

- CL-150

- Material

- Cast Iron / Stainless Steel / Carbon Steel

- Temperature

- -10C to +180C

- Media

- Water, Steam, Oil, Gas

- Structure

- Globe Type, Single Seated

- Power

- Pneumatic / Electric

- Port Size

- 15mm to 200mm

- Model

- CL-150

- Pipe Connection Type

- Flanged

- Bonnet Type

- Standard / Extended / Bellows Sealed

- Positioner

- Electro Pneumatic / Smart Positioner Available

- Suitable Fluids

- Corrosive / Non-Corrosive

- Ambient Temperature

- -10°C to 70°C

- Position Feedback

- Available on request

- Design Standards

- API 600, ASME B16.34

- Actuator Type

- Single Acting / Double Acting

- Leakage Class

- Class IV, V or VI per ANSI/FCI 70-2

- Control Signal

- 4-20mA / 0-10V / Pneumatic

- Packing Type

- PTFE V-Ring / Graphite

- Stroke Adjustment

- Yes

- Body Pressure Test

- Up to 20 Bar

- Body Finish

- Epoxy Coated

- End Connection Standard

- ANSI B16.5

- Painting

- Anti-corrosive coating

- Cv Value

- Refer to model specification

CL-150 Control Valves Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About CL-150 Control Valves

Control valve solutions provide high performance, easy maintenance, parts interchangeability, and long life. Designed to withstand harsh conditions, these are ideal for users in oil and gas, power, petrochemicals, steel, and other manufacturing sectors.

Our solution for the final control element used in modern plants includes control valve assemblies and accessories such as air sets, positioners, current to pneumatic converters, limit switches, and pressure gauges.

Honeywell offers the following types of control valves:

Single/ Double Seated Globe valves

Seated Angle Valves

Butterfly Valves

Mixing/ Diverting Seated 3-Way Valves

V-Notch Ball Valves

Full Bore Seated Ball Valves

The valves are available in different materials and with pressure and temperature ratings to suit user-specific applications. With Honeywells control valve solutions, users benefit from safe, efficient and cost-effective final control capability in a variety of industrial and commercial applications.

Versatile & Robust Design

The CL-150 Control Valve combines a globe-type body with a high-quality epoxy-coated finish, ensuring excellent corrosion resistance. It is suitable for a wide range of applications, from aggressive process fluids to standard water and steam control, thanks to its resilient materials and flexible actuator options. Available in sizes from DN15 to DN200, the valve supports vertical or horizontal installation and offers configurable bonnet, sealing, and position feedback choices.

Precision Control for Industrial Processes

Designed in line with API 600 and ASME B16.34 standards, the CL-150 provides precise regulation through options for stroke adjustment and smart or electro-pneumatic positioners. Its control signal versatility (4-20mA, 0-10V, or pneumatic) makes integration into modern industrial automation systems seamless, allowing accurate flow management and optimal process efficiency.

FAQs of CL-150 Control Valves:

Q: How do I select between a single acting and double acting actuator for the CL-150 Control Valve?

A: The choice between single acting and double acting actuators depends on your process requirements. Single acting actuators provide fail-safe positioning in one direction, while double acting actuators offer faster response and bi-directional control. Consult with your application engineer to determine the best fit for your process.Q: What fluids and temperature ranges are the CL-150 Control Valve suitable for?

A: The valve is engineered for corrosive and non-corrosive fluids including water, steam, oil, and gas. It operates efficiently from -10C to +180C, making it suitable for various industrial environments and process conditions.Q: When is position feedback recommended, and how can it be requested?

A: Position feedback is essential when remote monitoring of valve position is required for automation or safety systems. It is available on request and can be specified at the time of order to ensure your valve is equipped for your control system needs.Q: Where can the CL-150 Control Valve be installed and what mounting options are available?

A: This valve can be installed in either vertical or horizontal orientations. Its flanged ends conform to ANSI B16.5, ensuring compatibility with standard piping in industrial facilities.Q: What is the process for adjusting the valve stroke and why is it beneficial?

A: Stroke adjustment is facilitated by the actuator and allows fine-tuning of valve travel, ensuring precise flow regulation and improved control accuracy. This is particularly beneficial in applications requiring exact process parameters.Q: How does the anti-corrosive epoxy coating benefit valve performance and longevity?

A: The epoxy coating shields the valve body against harsh chemicals and environmental corrosion, extending service life and reducing maintenance frequency, especially in aggressive or high-moisture settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Control Valves Category

GLOBE VALVE

Price 2000 INR / Number

Minimum Order Quantity : 1 Number

Material : Other, Cast Iron, Cast Steel, Stainless Steel, Brass, Bronze

Pipe Connection Type : Other, Flanged / Threaded / Welded

Connection : Other, Flanged / Screwed / Buttweld ends

Standard : ISI / DIN / BS / ANSI

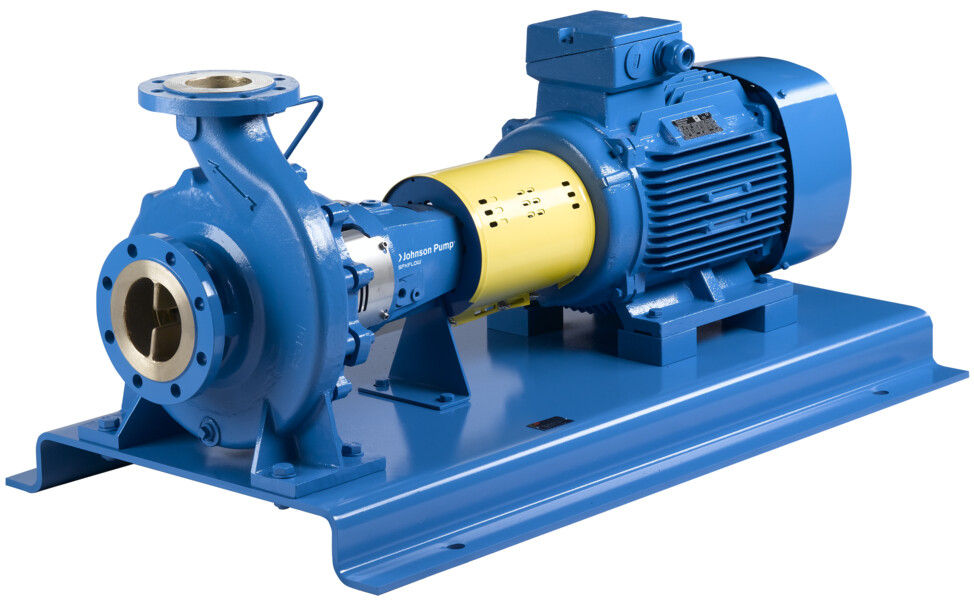

Centrifugal pump

Price 25000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Cast Iron / Stainless Steel

Pipe Connection Type : Other, Flanged

Connection : Other, Flange

Standard : ISO 2858 / DIN 24256

QUARTER TURN ELECTRIC ACTUATOR

Price 25000.0 INR / Number

Minimum Order Quantity : 1 Number

Pipe Connection Type : Other, Socket, Thread, Butt Welding Type, Flange Type, Glue

Connection : Glue

Send Inquiry

Send Inquiry